Variations of the microstructure (texture) of most materials, from structural elements to semiconductors, determine their consumer characteristics. For example, the most common way to deal with variations in the microstructure of structural materials is to improve its "safety margin" by increasing the use per unit of product. Thus, according to experts, the variation in the microstructure of alloys leads to an increase in the weight of the aircraft in 1.5 times, which, accordingly, affects the cost of the product and its operating expenditure throughout the life cycle.

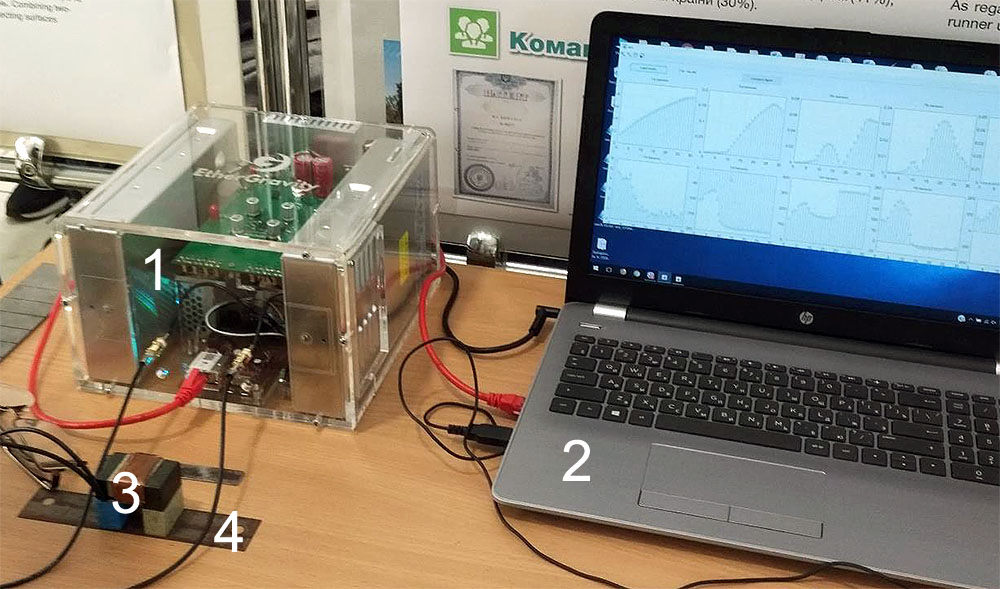

In comparison with the known technologies of non-destructive control, EG Structurescope reduces the time spent on the preparation and implementation of the control, the interpretation and the logging of results.

The device enables receiving of the integral characteristic of the microstructure of the material connected with its heterogeneity, enables monitoring of the variations of microstructure at the stages of both production and operation of products.

The structure of the global market for industrial non-destructive testing: US – 41%, EU – 29%, rest of the world – 30%. The world market capacity reaches $10 billion per year (Ukraine is estimated at $7 million per year). Over the past 10 years, the market has been growing at least 12% a year.

At present, the technology is being patented in the US with the advancement of national patents in the EU.